Details

| Classified ID | 11695 |

| Date Updated: | June 21, 2018 |

| Price | Call For Pricing |

| Condition | New |

Manual Saddle MachineCGM-1 Cold Cutting Machine

The rugged and powerful CGM-1 Pipe Cold Cutting and Bevel Machine cuts and bevels pipes or shells ranging from 6 to 72 inches (152 – 1826mm) in diameter with a wall thickness of 1⁄4” to 1” (6 – 25mm). The CGM-1, available in pneumatic and hydraulic models, can produce almost any type of pipe end configuration imaginable including standard bevels, “J” preps and lands by simply changing the cutting and beveling blades. The machines will cut and bevel any machineable material such as carbon steel, stainless steel, ductile iron, cast iron, and most other alloys without spark or flame. A second cut is not required as the machine bevels both sides of the cut simultaneously.

The Pneumatic driven CGM is designed primarily to cut and bevel thinner wall lower tensile strength pipes, while the hydraulic driven CGM has the brute strength required for the continuous cutting of heavier wall and higher tensile strength pipes. All machines are equipped with blade shut off valve that shuts off air or hydraulic pressure to the blade and drive motor when the blade guard is opened The hydraulic driven CGM has the brute strength required for continuous cutting of heavier wall and higher tensile strength pipes. Hydraulic CGM's closed loop hydraulic system insures proper lubrication to the motors extending the life of the machine. The maintenance free dual hydraulic motors are infinitely adjustable and deliver consistent horsepower to the cutting and beveling blades and drive motor. The Hydraulic model comes with two 10 meter hydraulic hoses with quick disconnects. Hoses can be made any length necessary to meet the customer requirement. The hydraulic driven CGM is the best choice, if noise is a consideration. A special model of the Hydraulic CGM is available for operation at ocean depth up to 130 feet.

The machine is held to the pipe by its tension/drive chain as it crawls around the pipe. The drive chain can be shortened or lengthened to accommodate any pipe or vessel diameter within its range. The CGM Drive System provides positive movement of the machine under all types of conditions for a smooth precise cut. No out-of-round compensation is needed as the machine follows the outside diameter of the pipe producing an even and consistent bevel.

Monarch Band Cutting Machine MagnaCut II and MagnaCut XM

Mathey Dearman's innovative MagnaCut magnetic Pipe and Plate Cutting Machine with remote controlled Torch Arm is an excellent choice when cutting a variety of pipe or plate wall thicknesses. Available in 2 models, MagnaCut attaches to any magnetically receptive surface. MagnaCut II can be easily identified by its green top utilizes permanent magnets and is designed for bare and lightly coated pipe. The MagnaCut XM identified by its red cover utilizes powerful rare earth magnets to adhere the machine to pipes with a coating up to .015” (.4mm) thick.

MagnaCut's speed and direction as well as torch arm speed direction can be remotely controlled from the motor control box minimizing the risk of injury to the operator. MagnaCut has a travel speed of 2” (51mm) to 32” (813mm) per minute around the pipe or along the plate. The MagnaCut has a pipe and tube cutting range of 6 5/8” (168mm) to unlimited on the outer diameter of the pipe and 24” to unlimited on the inside diameter of the pipe. MagnaCut cuts pipe or plate from 3/8” (10mm) to 2” (51mm) thick. MagnaCut's powerful drive motor enables the machine to cut both vertical plate and “I” beam. When extreme accuracy is needed a Guide strip can be made from a length of raw angle iron.

Whether you are a contractor, fabricator, or maintenance welder cutting bare or coated pipe or plate, MagnaCut is the machine for you. MagnaCut effortlessly cuts the pipe or plate cleanly and quickly producing a quality cut with little or no grinding time. MagnaCut comes in a rugged storage case with all service keys need for operation

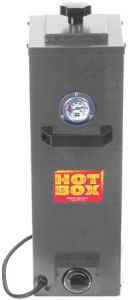

P8 Small Portable Holding Oven

The P8 Small Portable Holding Oven is excellent for the storage of welding electrode at the workstation. The oven stores up to 18lbs. / 8kg of 18”/ 45cm long welding electrodes in a humidity free environment to prevent the introduction of hydrogen in the weld puddle that causes weld cracking and porosity. Mathey Dearman's proven line of Small Portable Holding Ovens have been manufactured for over 35 years.

The Oven's square design is very rigid and less prone to incidental damage. An air gap between the oven chamber and the exterior wall acts as a natural insulation. The top of the oven has a 1/4" (6mm) lip to prevent moisture from entering the oven chamber. All electrodes are in contact with the heating element located in the bottom of the oven chamber to insure even heating of the electrode. The Oven exterior is powder coat painted to with stand shop abuse.

In 15 minutes or less a thermostat and thermometer can be added to the fixed temperature P8 oven with a screwdriver. All Ovens are equipped with an indicator lamp and 8” (2.4m) power cord. The oven is available in 24, 48, 72, 115 and 230 volts AC 50/60 Hertz. and 48vdc. All Ovens are CE approved.

© 2002 Mathey.com

All rights reserved. The Band with Band Crawler is the ideal tool for flame cutting pipe, when there is a minimum amount of clearance, in the trench or in a pipe run. The stainless steel Band provides a track that is square to the OD of the pipe on which the crawler tracks to cut the pipe. The Band crawler follows the precision flexible Band producing consistent bevel on severely out-of-round horizontal or vertical pipe as the band forms to the pipe shape. The heavy-duty Latching Mechanism of the band permits fast installation and closure of the band on the pipe regardless of the diameter. Alignment fingers on the band ends provide a positive closure and alignment of the band on the pipe.

Manual Saddle Machine

Dependable and tough, Mathey Dearman's Saddle Machines are designed specifically for critical pipe applications that require a high degree of cut quality and accuracy. The lightweight durable Saddle Machine is the standard throughout the welding industry, because of its long life, reliability and cutting accuracy.

Saddle Machines are available for pipe sizes 1 1⁄2” – 48” (38-1219mm). The 1SA and 2SA Saddle Machines are available with Spacer Bolts or Step Spacers and can be adapted to any new or old one-piece Saddle design.

Mathey Dearman's one-piece saddle can take abuse encountered during transportation and field use. The hard anodized Saddle, Ring Gear and Cap Ring are made of Space Age Aluminum to extend the machine life, improve rigidity and dependability. The machine is durable and substantially resistant to extreme heat or cold. They are precision-machined to produce precise movement of the oxy-fuel or plasma torch around the pipe. The Spacer Bolts or Step Spacers, located on either side of the Ring Gear, gives the machine performance required when cut quality and accuracy is critical.

The Short Saddle Machi Motorized Saddle Machine

Mathey Dearman’s Motorized Saddle Machines produce rapid and precise movement of the oxy-fuel or plasma torch around the pipe. The machine comes standard with a 115-vac Motor Control Box. The Motor Control Box can be adapted for other voltages with a Step Down Transformer.

Motorized Saddle Machines are available for pipe sizes 1 1⁄2” – 48” (38-1219mm). The 1SA and 2SA Motorized Saddle Machines are available with Spacer Bolts or Step Spacers and can be adapted to NEW or OLD one-piece Motorized Saddle design.

The Motorized Saddle Machine can be fitted with a variety of accessories such as Torch Shut Off Valve, Pro Model Rack Adjustable Torch Arm for out-of-round or over or undersize pipe, Contour Cutting Attachment and Template for precision saddle and miter cuts or Double Torch Arm to make two precision cuts simultaneously.

Skilled professionals as well as the novice can improve their proficiency, precision and cut quality, with the Mathey Dearman Short Saddle Cutting and Beveling Machine. The Motorized Unit will also lower production cost as it eliminates 85 percent grinding time.

ne is the most versatile of Mathey Dearman's line of cutting and beveling machine. The machine can fitted with a variety of accessories such as Torch Shut Off Valve, Pro Model Rack Adjustable Torch Arm for out-of-round or over or undersized pipe, Contour Cutting Attachment and Template to cut precision saddle and miter cuts or Double Torch Arm to make two precision cuts simultaneously.